Lower CO2 emissions in the pharma cold chain with recyclable containers

Sofia Wiwen-Nilsson

Head of Marketing and Communications

As part of Envirotainer’s sustainability efforts, and in line with being the industry's first climate neutral company, we have calculated the amount of CO2 emissions when shipping temperature-sensitive pharmaceuticals in our active containers. These calculations can be of help for pharmaceutical companies and service providers that want to evaluate different cold chain logistics alternatives in terms of sustainability. Continue reading to find out how much you can reduce CO2 emissions and how the calculations were done.

Safe transportation essential to reduce CO2 emissions in the pharma value-chain

One of the focus areas in our Sustainability Strategy is Driving resource efficiency in the value-chain[i]. An important part of resource efficiency is to minimize product loss. In the pharmaceutical value-chain, most CO2 emissions occur in pharmaceutical manufacturing, raw material sourcing and consumer use, whereas logistics only make up a few percentages. GSK has for example calculated that logistics makes up only 4% of its pharmaceutical value-chain[ii]. Sanofi has conducted similar calculations that show that upstream and downstream transportation make up 6,7% of Sanofi’s total greenhouse gas emissions[iii] while the fuel consumption of the medical sales vehicles fleet makes up another 1,4%.

Minimizing product loss is therefore a key priority in order to reduce CO2 emissions in the pharmaceutical cold chain. Having to discard pharmaceuticals that have been damaged during transport, and produce and deliver replacement products, implies a substantial negative environmental impact.

Minimizing product loss is therefore a key priority in order to reduce CO2 emissions in the pharmaceutical cold chain. Having to discard pharmaceuticals that have been damaged during transport, and produce and deliver replacement products, implies a substantial negative environmental impact.

Life cycle analysis of different cold chain logistics alternatives

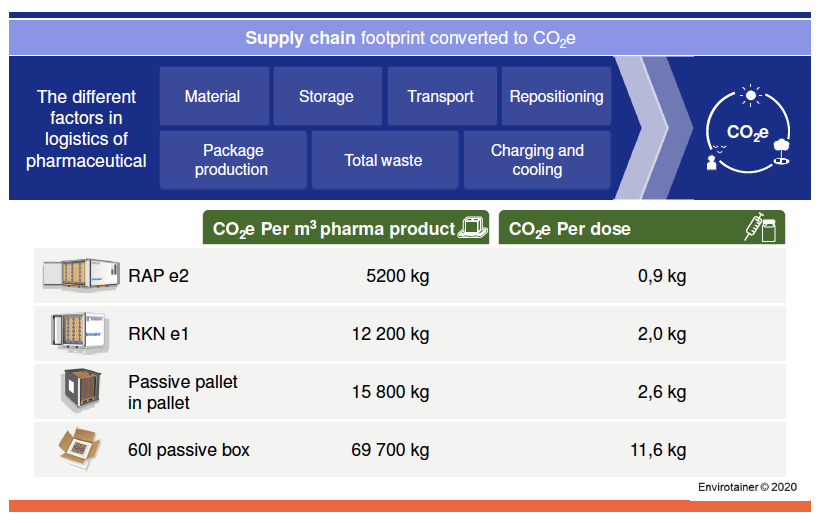

Different packaging alternatives also impact CO2 emissions in the pharmaceutical cold chain. To find out the CO2 emissions we conducted a life cycle analysis of two of our recyclable active containers:

- RAP e2, an active recyclable 5 EU pallets size container with electrical heating and cooling technology

- RKN e1, an active recyclable 1 EU pallet size container with electrical heating and cooling technology.

Three passive alternatives from competitors were also included in the calculations, all with Phase Change Material (PCM):

Three passive alternatives from competitors were also included in the calculations, all with Phase Change Material (PCM):

- A passive parcel container (60l)

- A passive single use 1 EU pallet size container (Traditional passive)

- A passive recyclable 1 EU pallet size container (PCM container).

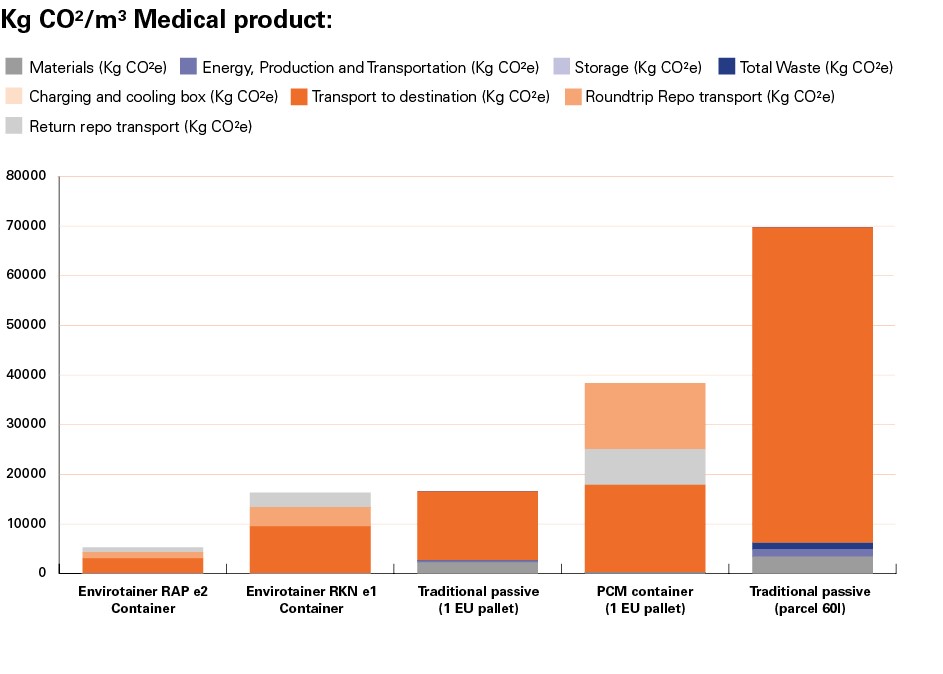

Emissions were calculated as Kg CO2/m3 Medical product, i.e. the amount of CO2 emissions, measured in kilogram, per cubic meter medical product being shipped.

Most container CO2 emissions occur when products are being shipped

As can be seen in the graph, most container CO2e emissions occur when medical products are being shipped (by air) to their destination (about 50%). Containers that are recyclable (the RAP e2, the RKN e1 and the PCM container) may need to be repositioned, either by air, road or by ocean. The return transport consists of repositions made by the customer and repositions that are handled by the supplier. The total emissions of the repositions are about 40-50% depending on the choice of transport.

Regarding the traditional single use container (Traditional passive) and the Parcel 60l, the manufacturing and waste comprise about 10-15% of CO2 emissions. The waste category includes disposal of medical products due to temperature control failure; this is assumed to be 5% for the Parcel 60l container.

Significantly lower CO2 emissions with recyclable active containers

According to our analysis, CO2 emissions are considerably lower with the recyclable containers. The main reason is that products can be shipped more efficiently, thanks to a large internal volume versus external volume. For example, our RAP e2 can fit up to 35% more pharmaceutical products than large passive solutions. Moreover, the Envirotainer containers are Unit Load Devices (ULDs) and adapted to the shape of the aircraft, meaning that they can utilize aircraft cargo space more efficiently than passive packaging. The analysis also shows that CO2 emissions (as well as costs) can be reduced by consolidating shipments to fewer shipments in larger containers.

To conclude, CO2 emissions in the cold chain can be significantly reduced through optimization of packaging, shipments, logistics flows and processes.

The image shows a summary of carbon emissions for different alternatives.

[i] Envirotainer, 2020: https://www.envirotainer.com/about-us/sustainability/driving-resource-efficiency-in-the-value-chain/

[ii] GSK, 2020: https://www.gsk.com/en-gb/responsibility/environment/carbon/

[iii] Sanofi, 2017: https://www.sanofi.com/-/media/project/one-sanofi-web/websites/global/sanofi-com/home/common/docs/download-center/carbon_footprint_c02_emissions_scope_1-2_may_2017.pdf/