Increased demand for RAP e2 when air cargo space plummets

Sofia Wiwen-Nilsson

Head of Marketing and Communications

The pandemic caused by the virus COVID-19 has led to a severe shortage of available air freight capacity. Many airlines have cancelled almost all international passenger flights, which has led to a decrease of air cargo space by 90%. Logistics departments at pharmaceutical companies are now racing to find new solutions for shipping their products. As companies try to maximize load volume efficiency, Envirotainer has noticed a significant increased demand for the large RAP e2 container.

“We see a strong increase in demand for all units since the COVID-19 pandemic started, especially for our RAP e2. Pharma companies want to get as much products on each plane as possible and for that the RAP e2 is unmatched,” says Cihan Likogullari, Global Key Account Manager at Envirotainer.

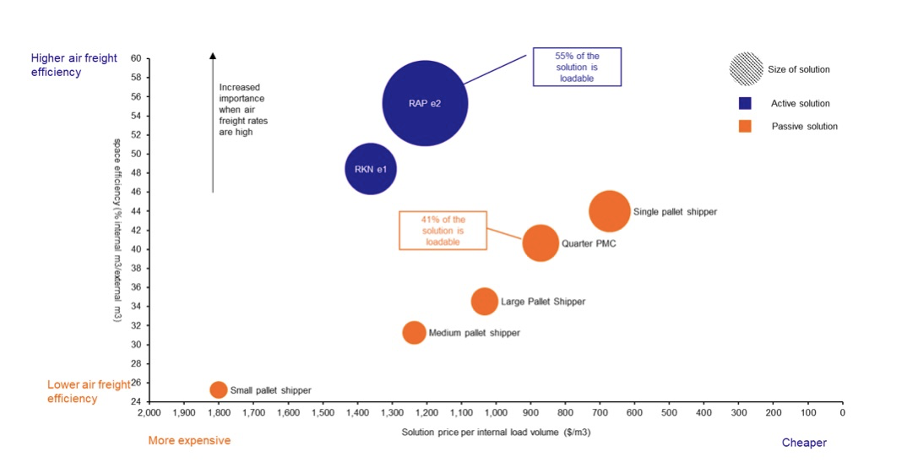

Maximizing payload efficiency

When comparing the active RAP e2 with smaller and less advanced passive units, it becomes clear that large ULDs are more cost efficient in the current market situation. The amount of insulation material in passive boxes reduces the payload volume per total volume. For small pallet shippers, insulation, cooling material and the box itself can make up a large part of the total volume, with only 25% payload efficiency. Another obvious advantage of RAP e2 is the active temperature control, which makes it a safer option for transporting sensitive pharmaceuticals.

Larger units such as RAP e2 have a significantly higher load volume efficiency compared to smaller passive solutions.

COVID-19 has changed the cost structure of pharma air freight

With a significant increase of air freight costs in the wake of the COVID-19 pandemic, the whole cost structure changes. As a result, many pharmaceutical companies risk using suboptimal freight solutions since different costs are evaluated separately from each other or are even on different budgets in different departments. It is important to get a complete picture of all costs, since there is an inverse proportion between the payload cost efficiency of the packaging solution and the air freight costs.

Example: Choosing the optimal air freight solution

One of Envirotainer’s clients needed to ship a large volume of life-saving pharmaceuticals. Their only option in the current situation was to charter an airplane. The charter cost was well over 1 million USD. They understood the value of optimizing the cargo space and reached out to Envirotainer to get help to evaluate different options. Small passive shippers were quickly ruled out since the insulation takes up most of the space. Envirotainer’s RAP e2 would load more than twice as much product in the cargo belly compared to the passive units. Instead, the choice was between large active units such as RAP e2, designed to fit 5 EU pallets, and large passive units, with space for 2 EU pallets. The choice was obvious. The large RAP e2 had a much higher load efficiency on the airplane.

”In Q1 & Q2 of 2020 Air freight prices skyrocket and supply is scarce. We are proud to be part of the solution to secure that patients receive their medicine on time and in good condition,” comments Karen Harbour, Strategic Account Manager at Envirotainer.